Pallet wrapping machine repair and its role in minimizing downtime

Everything about the Advantages of Spending in a High Quality Pallet wrapping Machine

Buying a top quality pallet wrapping device can change product packaging procedures. These machines offer enhanced Load security, ensuring that items stay safe throughout transportation. They also decrease material waste by using stretch film successfully. However, the benefits extend beyond these factors. Checking out the complete range of benefits discloses a deeper influence on productivity and safety and security within the workplace. Recognizing these advantages can result in even more enlightened company decisions. What various other elements should be taken into consideration?

Enhanced Load Security

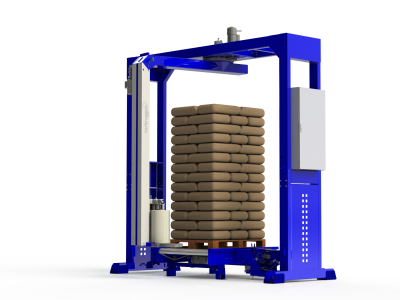

Boosted Load stability is an important advantage of investing in a pallet wrapping maker. This equipment plays an essential role in securing tons throughout storage and transport, lessening the threat of falling or shifting. By firmly wrapping pallets with stretch film, the tools guarantees that private things remain in position, protecting them from damage. Enhanced stability also enables more secure handling, decreasing the possibility of crashes and injuries in the workplace. With enhanced Load security, firms can make best use of space utilization in shipping containers and stockrooms, leading to more efficient operations. Eventually, the enhanced dependability of palletized tons promotes self-confidence amongst businesses, providers, and customers, improving total supply chain effectiveness and reliability.

Lowered Material Waste

Raised Performance and Rate

Investing in a pallet wrapping device considerably enhances effectiveness and speed in product packaging operations. These machines automate the wrapping procedure, permitting quicker prep work of products for shipment. By reducing the moment invested in hand-operated wrapping, companies can boost throughput and lessen traffic jams in the process. In addition, pallet wrapping devices provide constant outcomes, making sure that every Load is wrapped uniformly, which gets rid of the requirement for rework. This reliability not just speeds up procedures however also adds to much better inventory management, as products are planned for circulation extra promptly. Generally, the integration of a pallet wrapping device leads to a significant rise in efficiency, enabling companies to fulfill client needs better and keep an affordable side in the marketplace.

Enhanced Employee Safety And Security

Decreased Guidebook Handling Risks

Implementing a pallet wrapping maker considerably lowers manual handling dangers, enhancing general worker safety and security in industrial settings. Typically, workers by hand wrapped pallets, subjecting them to different physical strain and injury threats, consisting of lifting and turning. By automating this process, the machine decreases the requirement for workers to involve in repetitive, laborious activities that can lead to bone and joint problems. Furthermore, the consistent and safe and secure wrapping given by the device reduces the possibility of item dropping or changing during transportation, lowering the danger of accidents. This not just safeguards the workers however also assures the stability of the items being dealt with. On the whole, purchasing a pallet wrapping machine promotes a safer workplace atmosphere by mitigating manual taking care of risks successfully.

Boosted Ergonomic Layout

The enhanced ergonomic style of pallet wrapping machines significantly adds to enhanced employee safety and security and comfort. These equipments are engineered to reduce physical pressure by enabling drivers to keep a neutral body position throughout procedure. pallet wrapping machine repair. Features such as flexible elevations and easy to use controls allow reliable handling without excessive getting to or flexing. In addition, lots of models consist of security guards and automatic shut-off systems to avoid mishaps, further protecting employees. By decreasing the physical needs of wrapping pallets, these makers lower the threat of musculoskeletal injuries and tiredness, promoting a much healthier workplace. Overall, buying an ergonomic pallet wrapping machine not only improves efficiency however additionally shows a dedication to staff member health and safety and security

Affordable Packaging Service

While many businesses look for reliable ways to enhance their operations, a pallet wrapping device attracts attention as an economical packaging solution. By automating the wrapping procedure, business can significantly decrease labor costs and minimize Full Article the moment required for product packaging. This performance equates to higher productivity degrees, permitting companies to allocate resources to other necessary locations. Additionally, a pallet wrapping machine assists to lower product waste, as it uses the right amount of stretch film required to protect items without extra. This not just results in financial savings on packaging products however additionally improves the honesty of the products throughout transport. On the whole, purchasing a pallet wrapping equipment confirms to be a sensible financial decision for firms seeking to maximize their packaging procedures.

Modification and Versatility

Customization and versatility are vital advantages of buying a pallet wrapping maker, enabling companies to tailor their product packaging refines to certain product requirements. These equipments usually feature adjustable settings to suit numerous dimensions and shapes of pallets, guaranteeing ideal wrapping for various lots. Customers can choose the type of wrapping thickness, material, and tension to boost efficiency and meet details operational demands. Furthermore, advanced designs supply programmable features, allowing fast changes between various product packaging tasks without extensive downtime. This versatility not just streamlines the packaging process but also enhances performance by reducing hand-operated adjustments. Therefore, companies can effectively respond to changing demands while preserving a high standard of presentation and capability in their product packaging options.

Much Better Item Security During Transport

Making sure items get here undamaged at their destination is an important concern for businesses, and investing in a pallet wrapping device significantly boosts product protection throughout transport. These makers use a safe layer of stretch film around pallets, creating a secure system that reduces activity throughout shipping. This included security helps stop damage from changing tons, ecological variables, and effects that can occur throughout the transportation procedure. In addition, top quality pallet wrapping makers can provide dampness resistance, protecting items from moist problems. By efficiently securing and securing items, services can lower the threat of loss and pricey returns due to harmed goods. Ultimately, purchasing a pallet wrapping device proves essential for maintaining item honesty and ensuring client satisfaction.

Often Asked Inquiries

The length of time Does It Require To Install a Pallet wrapping Maker?

The setup time for a pallet wrapping device usually ranges from a couple of hours to a number of days, relying on the maker's complexity and the center's preparedness to fit the equipment.

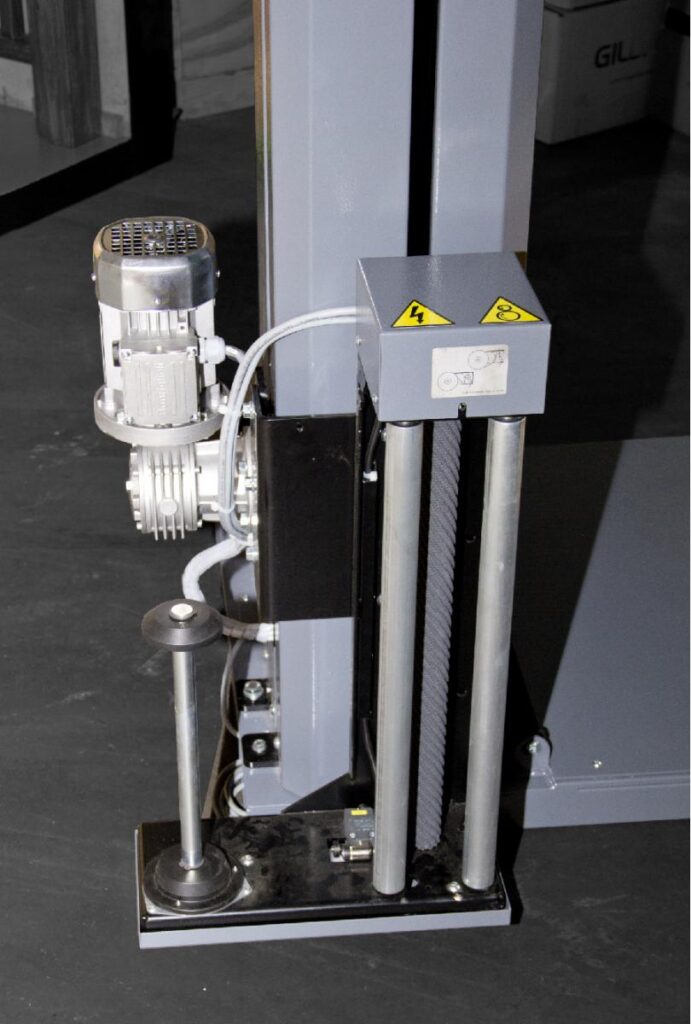

What Upkeep Is Needed for a Pallet wrapping Device?

Regular maintenance for a pallet wrapping equipment consists of lubricating relocating parts, inspecting and changing worn components, cleaning the device, and making sure correct calibration. Set up examinations aid prevent failures and prolong the tools's lifespan, improving functional performance.

Can a Pallet wrapping Equipment Handle Different Pallet Sizes?

A pallet wrapping machine can normally take care of various pallet sizes, depending upon its style and requirements. pallet wrapping machine repair. Adjustable settings and functions permit drivers to fit various measurements, guaranteeing safe and secure and efficient wrapping for diverse lots

What Is the Typical Life-span of a Pallet wrapping Equipment?

The average lifespan of a pallet wrapping equipment normally ranges click this link from 5 to 15 years, depending on the model, use regularity, upkeep methods, and operational atmosphere, influencing overall efficiency and long-lasting investment worth.

Exist Any Specific Training Needs for Operating These Machines?

The training demands for running pallet wrapping equipments usually why not look here consist of safety procedures, equipment procedure methods, and upkeep treatments. Correct training assurances safe use and takes full advantage of effectiveness, reducing the danger of mishaps and tools damages in the work environment.

Additionally, pallet wrapping makers supply consistent outcomes, making sure that every Load is wrapped uniformly, which removes the need for rework. Investing in a pallet wrapping equipment significantly enhances worker security by minimizing the risks connected with hands-on handling. Regular upkeep for a pallet wrapping machine consists of lubricating relocating components, inspecting and replacing worn elements, cleansing the machine, and making sure correct calibration. A pallet wrapping device can typically deal with numerous pallet dimensions, depending on its style and specs. The training demands for operating pallet wrapping makers normally include security methods, device procedure techniques, and upkeep procedures.